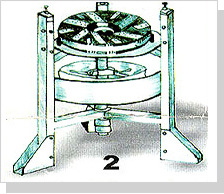

Information About Vertical Flour Mills

| |

|

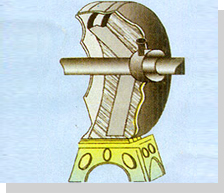

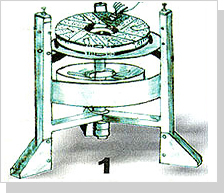

Firstly check the extent of the holes in the stones with the help of the bolts that tighten the fixed Stone to the cover plate of the mill. The length of the bolts should not be more than the extent (depth) of the holes. If it happens to be more, excessive tightening will make the stone slip off the backing plate of the stone and the stone will be useless.While fixing the Runner stone (the stone that moves) with the shaft, do not let the plates be damaged by striking of stones by any kind of hammer. Fit the shaft carefully and cautiously, without throwing it on the ground or striking it with any hard tool.Secure the stone to the seat of the shaft properly with shafting bolts. Now, let the shaft pass through the hole of the runner stone, and be sure that it is in correct position. If you find it loose, use packing of a thin tin sheet, and fix it in such a manner that the shaft remains straight in the hole. If on fixing the packing, the grain would not be ground properly, and will contain more husk, chaff etc. The stone will throw flour on one side and broken grains on the other. |

|

| |

|

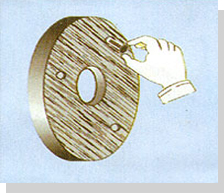

Apply some colour on the faces of both the stones , before fitting them in the mill. Now, tighten the stones only enough to let you move the Runner stone easily with your hand. Start the motor or the engine to run the mill. You will seen that the colour has rubber off , at the places where the stones do not meet properly In the places o the faces of the stones where colour has rubbed off, chip adequately, and test the stones again by moving them. Put the mill to work only after correcting the faces of the stones.Before milling flour for your customers, feed some old flour into the mill, so that the surface of the stones are polished. If you cannot feed old flour you can put water into the mill and make the stones move for a while. Flour milled after all these necessary operations would meet the satisfaction of your customers and you will not have any complaints there after. |

|

| |

|

Necessary Precautions About Vertical Flour Mills

| |

|

-

Do not grind the stones, without feeding anything into the mill. If you do so, you will make the faces of the stones weaker.

-

While making adjustments, press the lever very gently, so that the stones do not become hot and the danger of damaging the faces of the stones is eliminated.

-

Whenever you open the mill, clean off the flour which may have coagulated around the Fixed Stone, so that there remains no possibility of the stone getting damaged.

|

|

| |

|

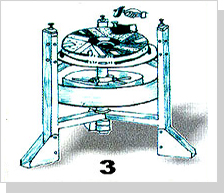

Information About Horizontal Flour Mills

| |

|

Firstly the Runner stone is to be placed on the shaft which automatically sets itself but it should not be damaged by any kind of hammer. The stone is to be carefully and cautiously fit without throwing it on the ground or striking it with any hard too. There is no trouble as the stone and shaft are in the taper shape and just with a slight adjustment both adjust automatically.Anyhow it is to be ensured hat it has come to the correct position. If it does not fit well, the grain would not be grounded properly, and will contain more husk, chaff etc. The stone will throw flour on one side and broken grains on the other. |

|

| |

|

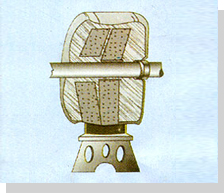

Apply some colour on the face of the runner stone.Now the fix stone be laid over the Runner Stone. Then the Fix Stone be moved slightly with the help of the hand. It may be noticed that the colour has rubber off at some places which will indicate that it requires slight adjustment. Therefore whenever the colour had rubber off, those particular places be chipped off. And then again be tested by moving them. When finally colour rubbing stops it will indicate that the Stones have fit in well. |

|

| |

|

Before milling flour for your customers, feed some old flour into the mill, so that the surface of the stones are polished. If you cannot feed old flour you can put water into the mill and make the stones move for a while. Flour milled after all these necessary operations would meet the satisfaction of your customers and you will not have any complaints there after. |

|

| |

|

Necessary Precautions About Horizontal Flour Mills

| |

|

-

Do not grind the stones, without feeding anything into the mill. If you do so, you will make the faces of the stones weaker.

-

While making adjustments, press the lever very gently, so that the stones do not become hot and the danger of damaging the faces of the stones is eliminated.

-

Whenever you open the mill, clean off the flour which may have coagulated around the Fixed Stone, so that there remains no possibility of the stone getting damaged.

|

|

| |

|

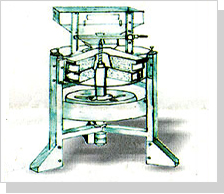

Information Abour Spare Parts

|